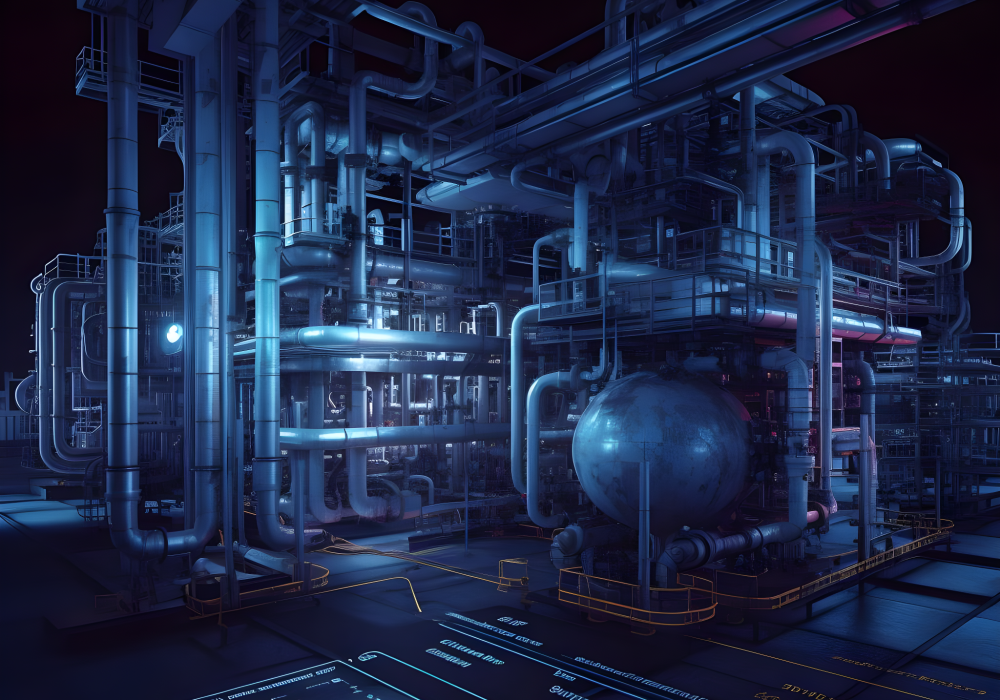

Real-Time Oil Condition Monitoring

Protect Your Investment with Real-time Oil Condition Monitoring and Intelligent Maintenance Optimization

Extend Equipment Life - Monitor Oil Conditions in Real-time

Real-time continuous oil condition analysis with integrated intelligent equipment maintenance optimization analytics. Detects and measures all and any wear and contamination. Any industrial or commercial application – any oil type.

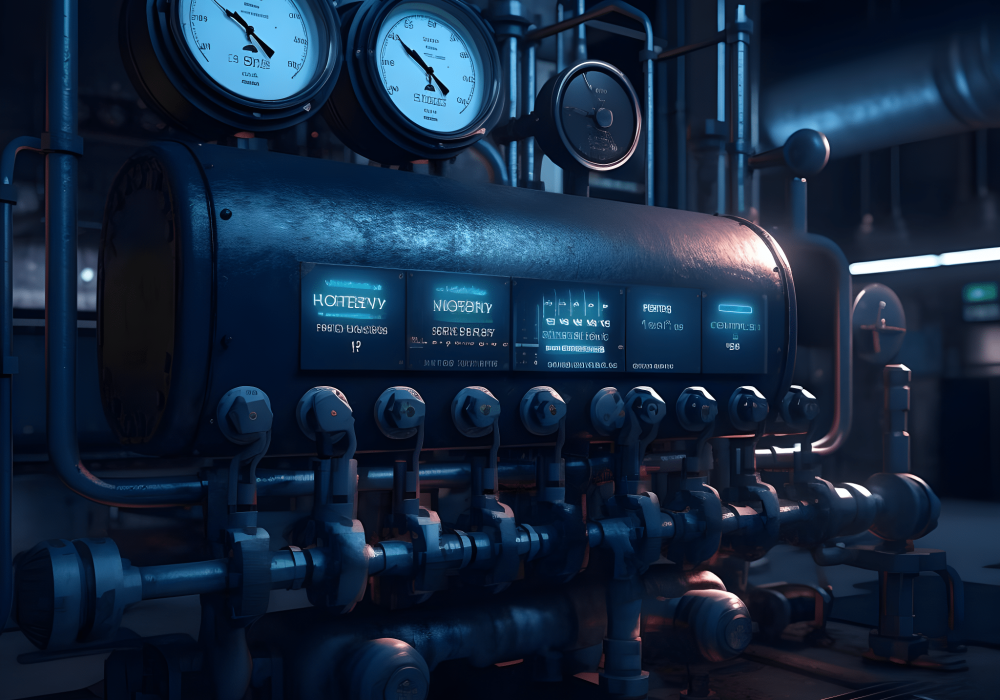

Monitor Your Oil Conditions with Precision

The condition of oil is directly and accurately correlated to the maintenance and health status of equipment. Therefore if oil condition can be accurately analysed and interpreted in real time, equipment health status can be deeply and easily understood enabling appropriate maintenance decisions to be made based upon facts.

Key features

Real-time Oil Condition Monitoring

Continuous monitoring of oil conditions in real-time.

Integrated Maintenance Optimization Analytics

Intelligent equipment maintenance optimization analytics to provide insights for effective decision-making

Detection and Measurement of Wear and Contamination

Detects and measures any wear and contamination in oil

Versatility

Suitable for any industrial or commercial application, and compatible with any oil type

Key Benefits

Increased Equipment Lifespan

Early detection and resolution of equipment issues based on real-time oil condition analysis leads to longer equipment lifespan

Enhanced Maintenance Efficiency

Real-time insights into equipment status improve the efficiency and effectiveness of maintenance decisions

Cost Savings

Early detection and resolution of equipment issues result in cost savings from avoiding major breakdowns and costly repairs

Improved Safety

Early detection and resolution of equipment issues also improves safety for workers and reduces the risk of catastrophic equipment failures